In treatment plants, selecting the right screen is vital for increased productivity and trouble-free operation.

If the solid wastes are effectively retained at the initial phase, the subsequent treatment process can be accomplished with a higher performance.

Sismat chooses the most appropriate screen for your plant according to the required bar spacing, screen mountain angle, channel width and depth.

Areas of Use

- Domestic and Industrial waste water treatment plants

- Water treatment plants

- Pumping stations.

- Water intake structures (from river or sea)

Types of Screens

|

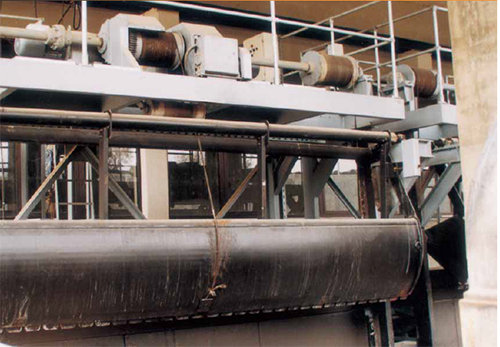

Travelling Band Screen (DBI) It is most widely used in water intake structures (from sea or river) in plants that consume water in great amount, e.g., cooling towers in steel factories and power plants, or carrying sugar beet in sugar factories. |

|

|

Plastic Conveyor Screen (PKI) With polymide screen elements that are highly resistant to many chemicals and a wide range of pH values, this model provides a great superiority particularly in industrial wastewater treatment plants. |

|

|

Linear Mechanical Screen (LMI) Since it does not have any moving parts that operate underwater, wastes do not stick to the screen and inhibit its operation. |

|

|

Cable Operated Screen(HKI) Where the water level is high, this is the best solution. It is widely preferred and implemented in pumping stations where level differences is high. |

|

|

Travelling Grab Screen (KGI) It is the most economical solution for cases where the channel width is large or where there is a need to clean several screen channels constructed in parallel. |

|

|

Multi-raked Mechanical Screen (OTI) The chain mechanism, to which multiple rakes are mounted, is placed in front of stationary bars. |

|

|

Back Raked Mechanical Screen (ATI) The chain mechanism, to which multiple rakes are mounted, is placed in the back of stationary bars. |

|

|

Step Screen (SSS) It has step-shaped conveying lamas that pass through step-shaped stationary bars. The conveyor action carries the waste, held by screens, continuously one step up and takes them out of the channel. |

|

|

Helical Basket Screen (SKI) It consists of a cylindrical screen and a spiral that cleans it. Its most important feature is that it does note require the use of screening press because it simultaneously performs squeezing while conveying the screenings out to the channel. |

|

|

Externally Fed Rotary Drum Screen (DAT) It is a very fine screen mounted to the pipeline it s used mostly for the very fine screening of suspended solid wastes of 0,25-30 mm. |

|

|

Static Screen (STE) In static screen, there is no mechanical part. It fine screens by gravity. It is widely used at the treatment plants of textile, food and alcohol industries and paper mills. |

|

|

Rotary Disc Screen (DDE) Rotary Disc Screen is a fine screen for filtration between 20-200 microns. Preferred especially in textile industry and paper mills, this screen is used for protection of heat exchangers and for process water preparation purposes. |

|

|

Internally Fed Rotary Durm Screen (IAT) It is comprised of a drum, manufactured as perforated plate or wedge wire, bearing system, water distribution weir and water spraying system. |

|

|

Screening Compactor (SSC) All screenings removed by screens always contain water and thus their volume is swollen.Our Screening Compactors are capable of dewatering the screenings up to 70% dryness. |

|